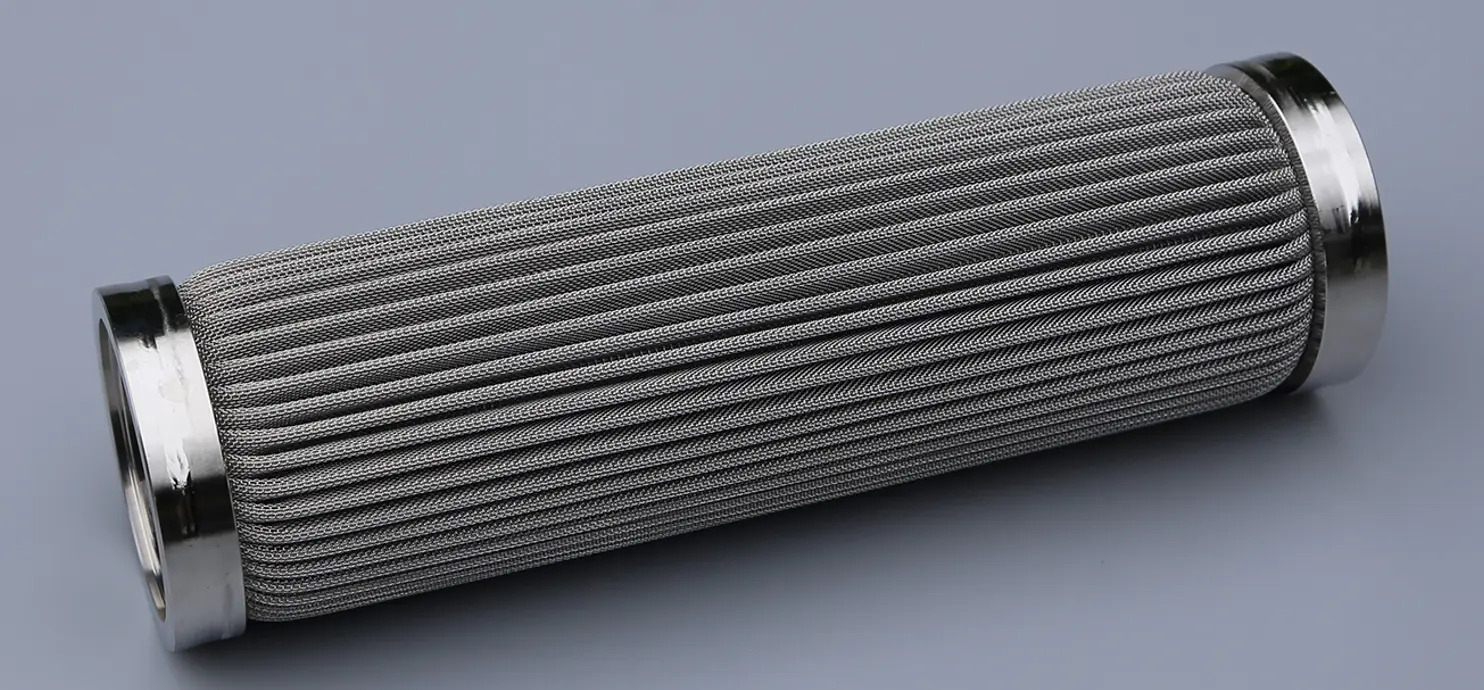

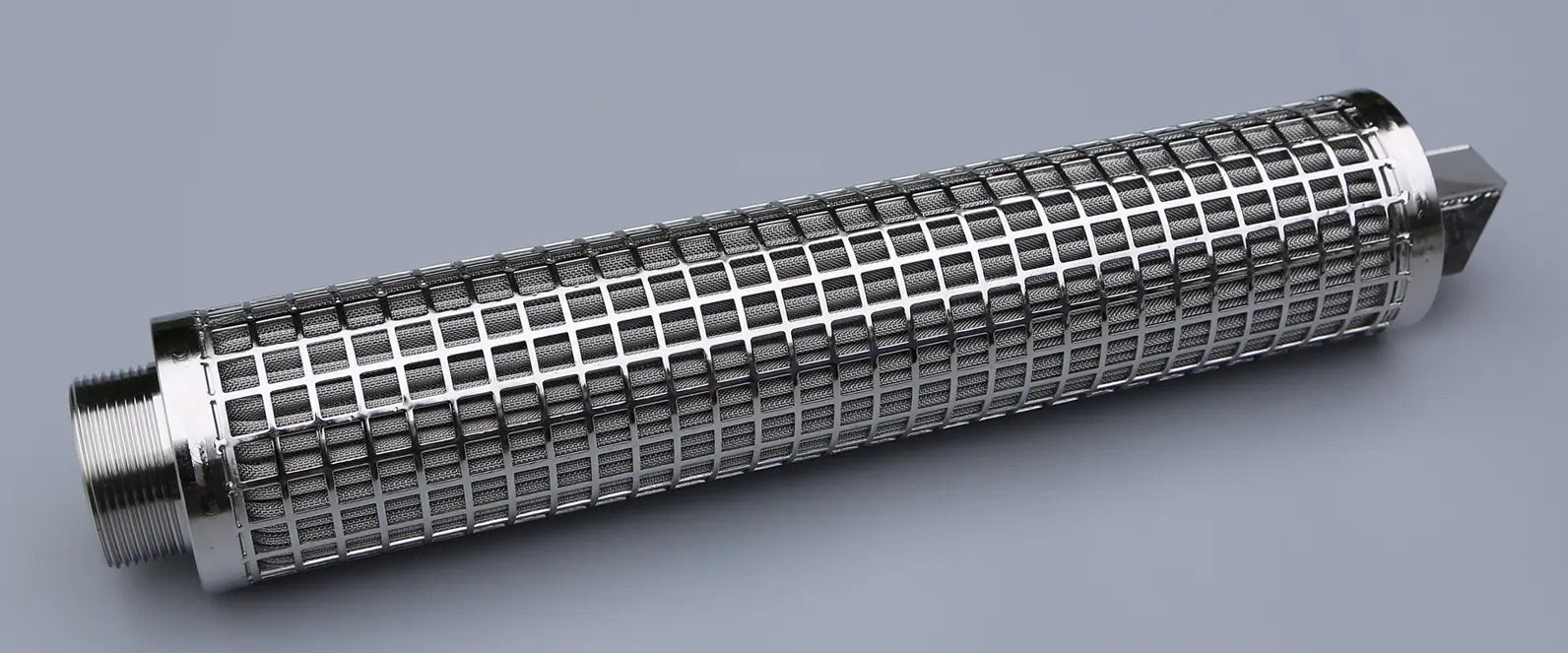

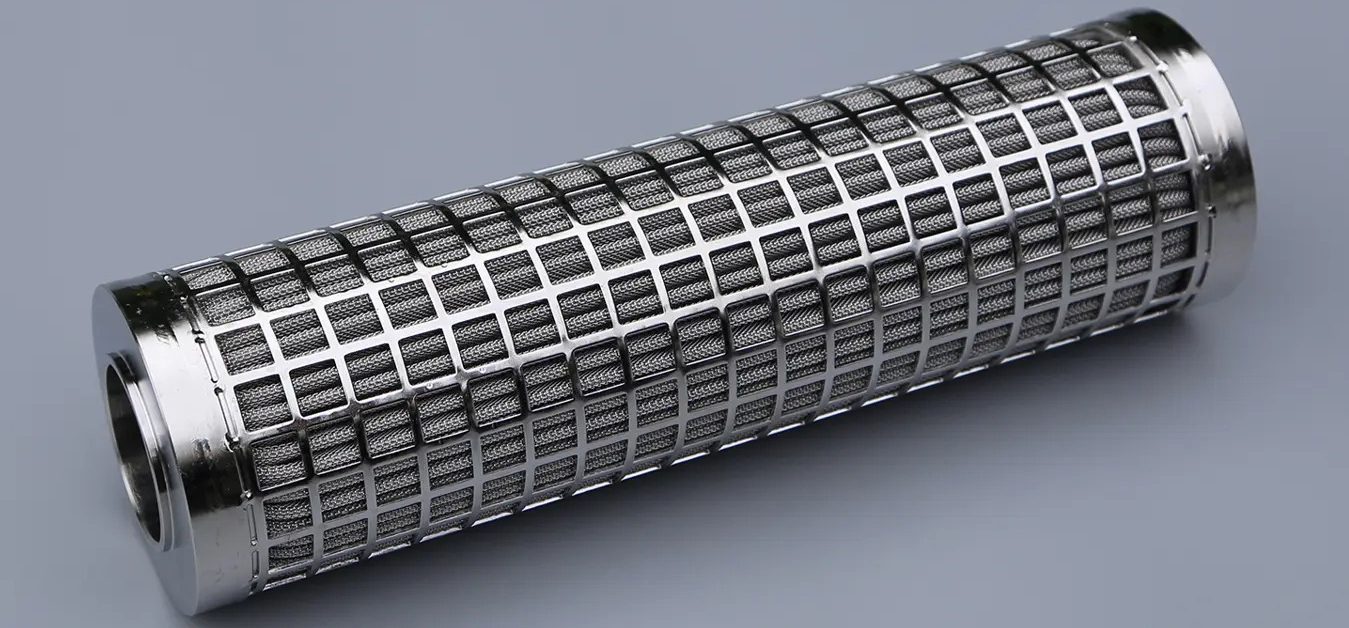

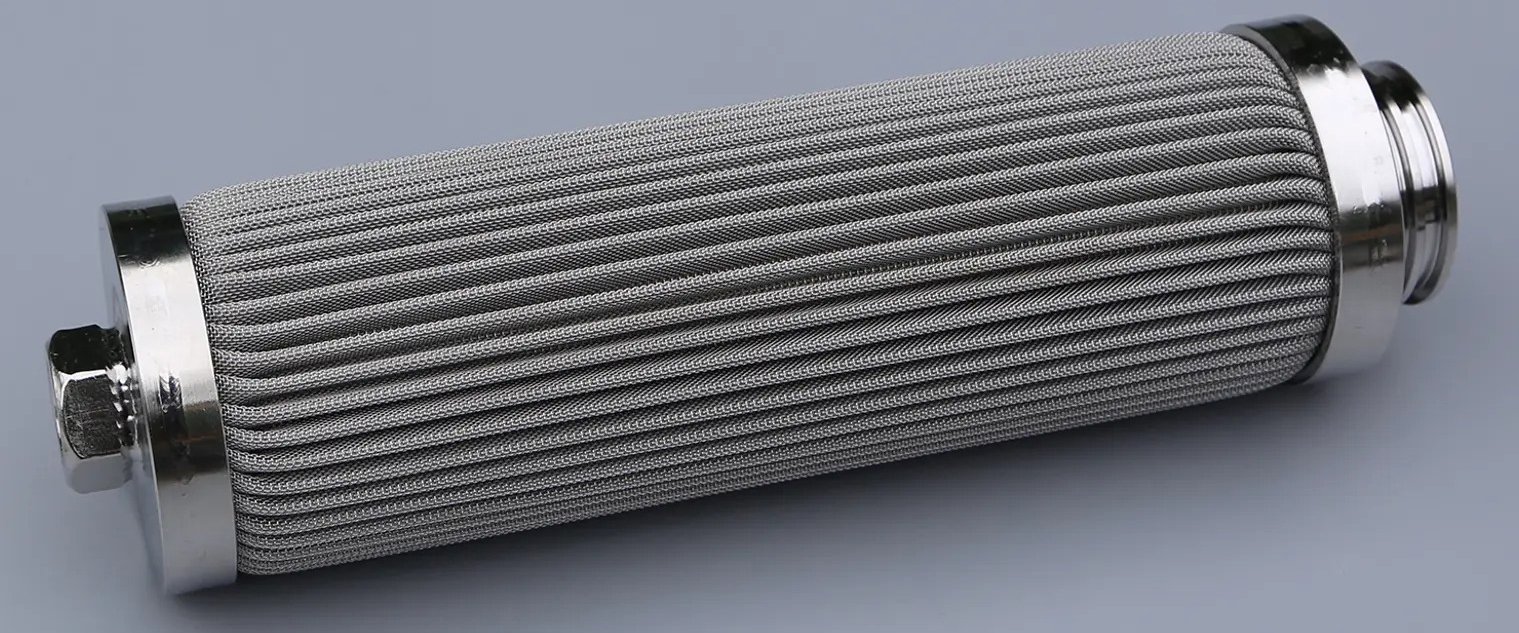

Melt Polymer Strainer Roj Pleated Lim

Taw qhia

Pleated cov ntxaij lim dej yog tsim los ntawm cov ntaub ntawv xov xwm pleated, ua rau lawv zoo dua li lwm cov lim dej hauv cov ntsiab lus ntawm kev ntes cov teeb meem thiab txhim kho huab cua lossis kua dej zoo.Lawv yog siv nyob rau hauv ntau yam kev siv, xws li HVAC systems, thoob dej yug ntses, thiab dej systems, uas tau txais txiaj ntsig los ntawm qhov nce saum npoo av thiab muaj zog lim zog ntawm pleated lim.Pleated cov ntxaij lim dej kuj tseem tsim los nrog cov ntsiab lus tshwj xeeb hauv siab thiab tuaj nyob rau hauv ntau hom duab thiab ntau thiab tsawg, tso cai rau lawv siv tau zoo thiab muaj txiaj ntsig hauv ntau qhov chaw.

Specification

Lub ntsiab lim tawm ntawm Pleated Filter yog tsim los ntawm stainless hlau woven hlau mesh thiab stainless hlau fiber ntau sintered xav.

Cov ntaub ntawv ntawm lub ntsiab lim xov xwm muaj xws li 304, 304L, 316, 316L, 904L, Monel, Hastelloy thiab lwm yam.

● Pom tus nqi: 3-200μm

● Kub: -50 ℃ -800 ℃

● Txoj kab uas hla: 14-180mm, Ntev: 35-1500mm

● Customized kuj muaj.

| Kev Ntsuas Ntsuas Ntsuas (μ) | Bubble Piont Siab (Pa) | Qhov nruab nrab cua permeability (l / dm2 / min) | Thickness (mm) | Qhov hnyav (g / m2) | Porosity (%) | Dirt Holding Capacity (mg / cm2) |

| 3 | 12300 Nws | 9 | 0.35 Nws | 975 ib | 65 | 6.40 Nws |

| 5 | 7600 ib | 34 | 0.34 ib | 600 | 78 | 5.47 ib |

| 7 | 5045 ib | 57 | 0.27 ib | 600 | 72 | 6.47 ib |

| 10 | 3700 ib | 100 | 0.32 ib | 600 | 77 | 7.56 ib |

| 15 | 2470 ib | 175 | 0.37 ib | 600 | 80 | 7.92 ib |

| 20 | 1850 | 255 | 0.49 ib | 750 | 81 | 12.44 Nws |

| 25 | 1480 | 320 | 0.61 ib | 1050 | 79 | 19.38 Nws |

| 30 | 1235 ib | 455 | 0.63 ib | 1050 | 79 | 23.07 Nws |

| 40 | 925 ib | 580 | 0.66 ib | 1200 | 77 | 25.96 Nws |

| 60 | 630 | 1000 | 0.70 ib | 750 | 87 | 33.97 ib |

Daim ntawv thov

1. Loj pom cheeb tsam, Ntau qhov kev lim dej raug

2. High porosity tus nqi, Zoo heev huab cua permeability thiab pom muaj peev xwm.

3. Zoo av tuav peev, Economical.

4. Kub kub kuj, corrosion kuj thiab lwm yam.

5. Ib qho yooj yim tu, Recyclable.

Yam ntxwv

1) High polymer kev lag luam

2) Petrochemical kev lag luam

3) Pharmaceutical thiab zaub mov refining kev lag luam

4) Kev kho dej

5) Machinery thiab nkoj kev lag luam

6) Cua purification

7) Lwm yam: Kub kub, siab viscosity, siab siab.

Zaub